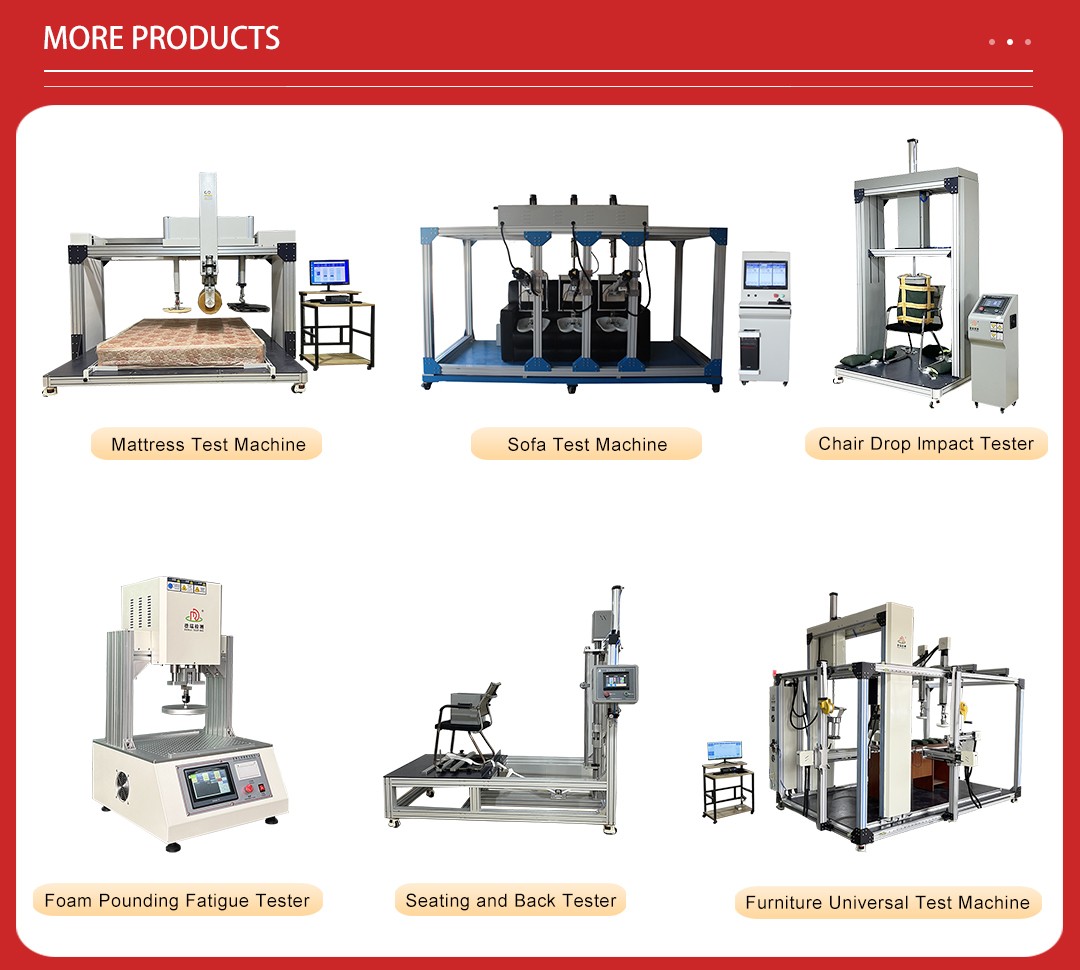

The Chair Impact Test Machine is a specialized piece of equipment designed to assess the durability and resilience of chairs under simulated drop conditions. This machine is crucial for evaluating the ability of chairs to withstand heavy impacts and fatigue stresses caused by vertical forces on the seat.

1. Advanced Design: The machine is constructed with a robust aluminum frame and base, ensuring stability and longevity .

2. Secure Fixation: It employs a double-wing system to securely hold the chair in place during testing, simulating real-world drop scenarios .

3. Power System: The system includes a drive device with an imported motor, speed reducer, axel, upper and lower limitations, spring, electromagnet, and a dropping device that consists of a dropping standard board, magnet, safety spacing push rod, automatic return, digital altimeter, encoder, and hydraulic pressure buffering device .

4. Control System: The machine utilizes an electromagnet sensor control, offering an easy-to-operate interface with a high degree of automation .

5. Safety Features: It is equipped with upper and lower limitation devices and an automatic power-off feature in case of electricity leakage, ensuring operator safety .

6. Customizable Drop Height: The drop height range is adjustable from 400mm to 1500mm, and can be customized to meet specific testing requirements .

7. Impact Simulation: The machine can simulate both seat repeated shocks and one-time impacts on the seat surface, providing a comprehensive evaluation of chair durability .

8. Efficient Operation: It features an automatic return mechanism and digital altimeter for precise control, along with a hydraulic buffer mechanism to reduce impact noise .

9. Compliance with Standards: The Chair Impact Test Machine is designed to comply with standards such as BIFMA X5.1 and X5.5, ensuring accurate and standardized testing procedures .

Office Chair Rotating Testing Machine |

Mode | HD-F731 |

Counter | 0-999 , 999 , memory , output control |

Impact sandbags diameter | 16 inch 125 pounds standard sandbbags |

Static pressure mould diameter | 8 inch , 165 pounds briquetting |

Impact speed | 10-30 times/minute or specified |

Static pressure speed | 10-30 times/minute or specified |

Cylinder stroke | 0-300mm |

Rail height | 90-135cm |

Machine size | 270*85*80cm |

Power | AC220V , 3A |

BIFMA requirements | impact 100000 times+ static pressure 20000 times ( left )

+static pressure 20000times ( right ) |